Aluminium Beryllium (AlBe) Master Alloy is available in AlBe1, AlBe3, and AlBe5 grades, or can be customised to meet specific beryllium content requirements. It is used for beryllium addition in both aluminium and magnesium alloys.

In magnesium alloys, the addition of AlBe reduces burning loss and oxidation slag, resulting in cleaner melts and higher-quality magnesium alloys.

In aluminium alloys, AlBe enhances mechanical properties such as strength and ductility, while also reducing oxidation and corrosion at elevated temperatures, ensuring greater reliability in demanding applications.

| PRODUCT | Be(%) | BALANCE | SHAPE |

| AlBe5 | 5 | Aluminum | CCB, Stick, Coil |

| AlBe3 | 3 | Aluminum | CCB, Stick, Coil |

| AlBe1 | 1 | Aluminum | CCB, Stick, Coil |

Key Features

- Reduces burning loss during alloying

- Minimises oxidation slag in magnesium alloys

- Improves ductility and plasticity

- Enhances strength and overall mechanical performance

- Provides improved high-temperature stability and corrosion resistance

Available Specifications

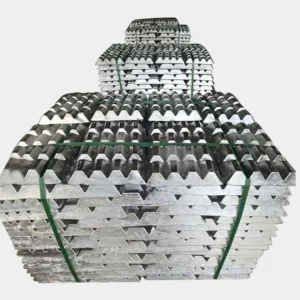

AlBe master alloys can be supplied in the following forms:

- Cut Casting Bars (CCB, 100–1000 g/bar): AlBe1, AlBe3, AlBe5

- Sticks and Coils: AlBe1, AlBe3

+84-(0)24-6674 6063