Aluminium Copper (AlCu) Master Alloy is available in AlCu10, AlCu20, and AlCu50 grades, or can be customised to meet specific copper content requirements. It is primarily used for copper addition in aluminium alloys.

Copper is a critical alloying element that provides solid solution strengthening and, through the precipitation of CuAl₂ during ageing, delivers a strong ageing strengthening effect. In aluminium alloys, the optimal strengthening range is typically 4%–6.8% copper content, which is why duralumin alloys often fall within this range. Adding copper via AlCu master alloy ensures uniform distribution, controlled composition, and reliable strengthening during alloying.

The addition of copper improves the mechanical properties, hardness, and machinability of aluminium alloys, making AlCu master alloy an essential material in aerospace, automotive, and industrial applications.

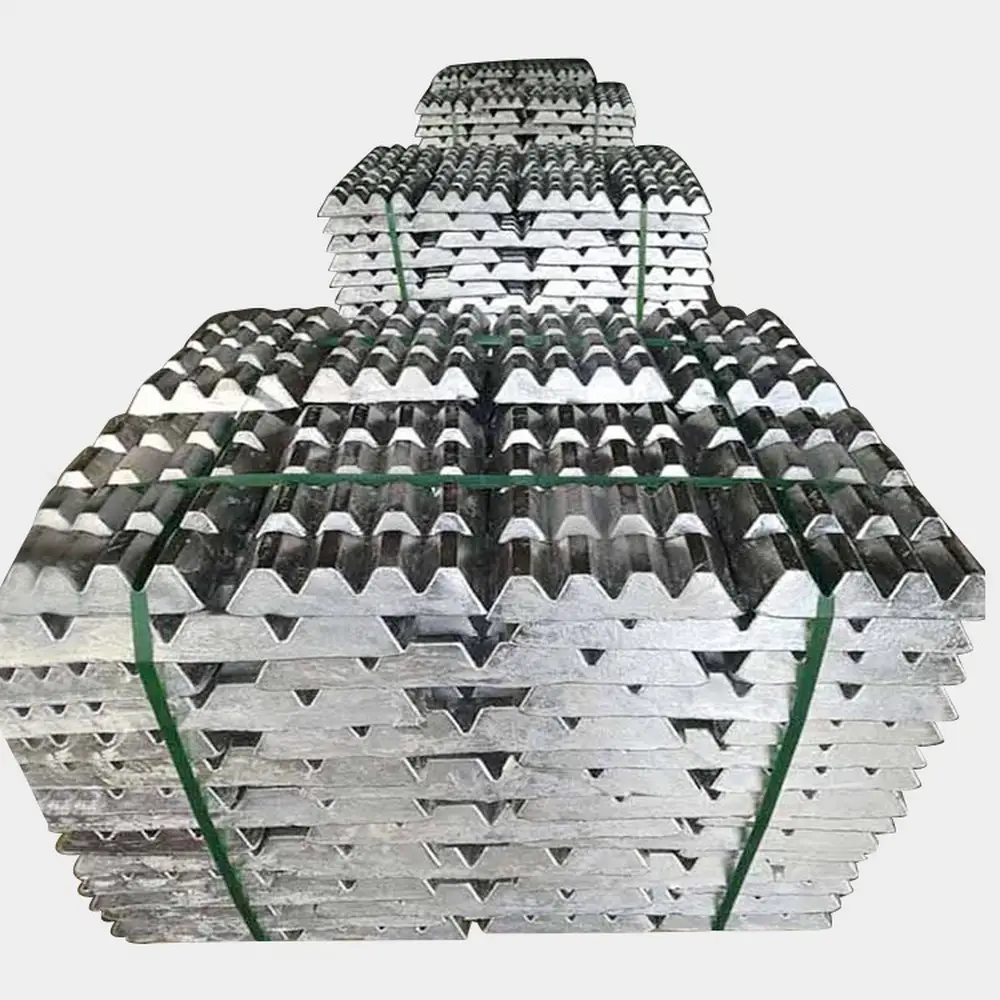

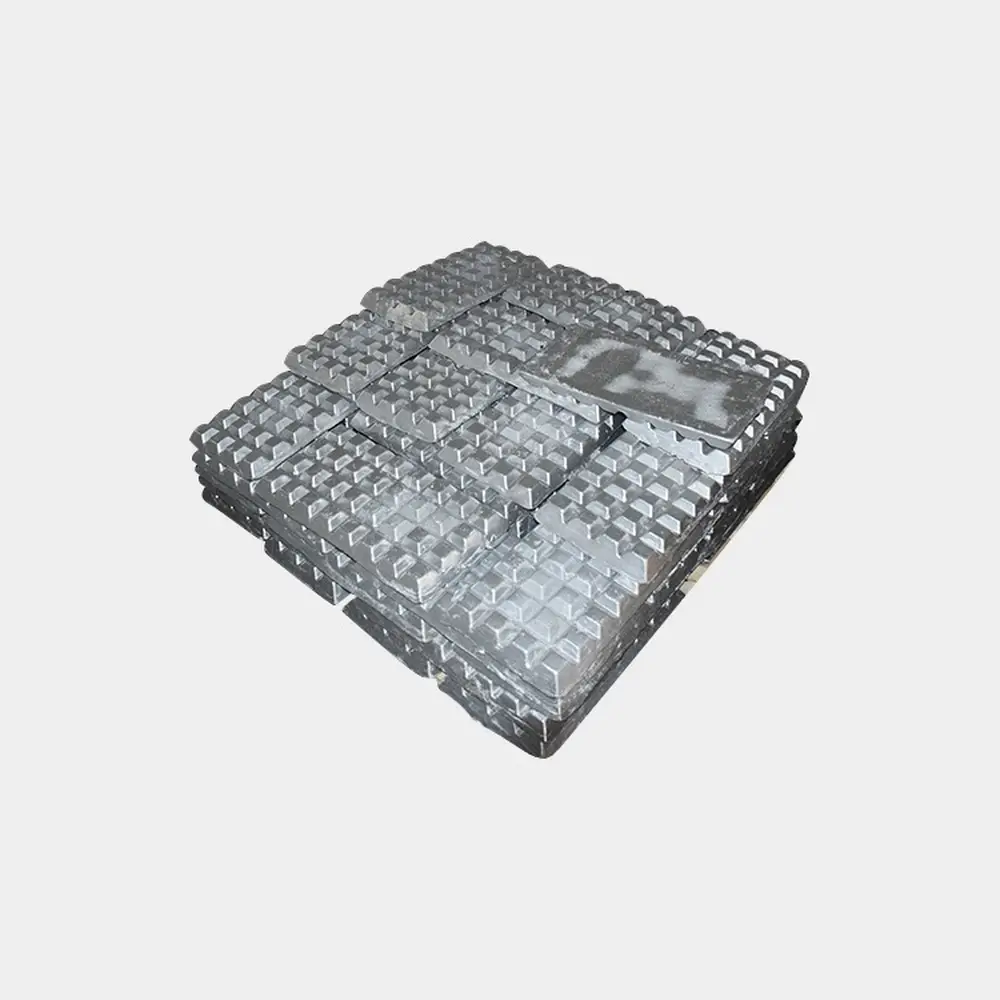

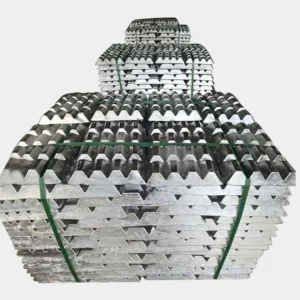

| PRODUCT | Cu(%) | BALANCE | SHAPE |

| AlCu10 | 10 | Aluminum | Waffle |

| AlCu20 | 20 | Aluminum | Waffle |

| AlCu50 | 50 | Aluminum | Waffle |

Key Features

- Uniform grain distribution, reducing segregation

- Strong ageing strengthening effect (via CuAl₂ precipitation)

- Improves the machinability of aluminium alloys

- Enhances overall mechanical properties

- Low addition temperature with minimal copper burning loss

- Contributes to energy savings and extended furnace life through reduced furnace temperature requirements

Available Specifications: Waffles (6–8 kg/waffle)

+84-(0)24-6674 6063