Aluminium Boron (AlB) Master Alloy is available in AlB3, AlB5, and AlB8 grades, depending on boron content. It is primarily used for boron addition and grain refinement in aluminium alloys.

With a low addition temperature and minimal boron burning loss, AlB master alloys release a large number of AlB₂ high-melting-point particles into the molten aluminium. These act as nucleation sites during solidification, refining the grain structure, enhancing uniformity, and significantly improving the strength, ductility, and mechanical performance of aluminium castings.

In addition to its refining effect, Aluminium Boron master alloy also provides a notable improvement in the conductivity of aluminium wires and cables, making it an essential material in electrical applications.

| PRODUCT | B(%) | BALANCE | SHAPE |

| AlB8 | 8 | Aluminum | CCB, Waffle |

| AlB5 | 5 | Aluminum | CCB, Waffle |

| AlB3 | 3 | Aluminum | CCB, Waffle |

Key Features

- Uniform grain distribution, reducing segregation

- Prevents cracks and minimises casting defects

- Enhances the surface quality of aluminium products

- Improves ductility and plasticity

- Low addition temperature with reduced boron loss

- Strengthens the mechanical properties of castings

- Improves electrical conductivity in aluminium wires and cables

Available Specifications

To meet diverse industrial requirements, AlB master alloys are supplied in the following forms:

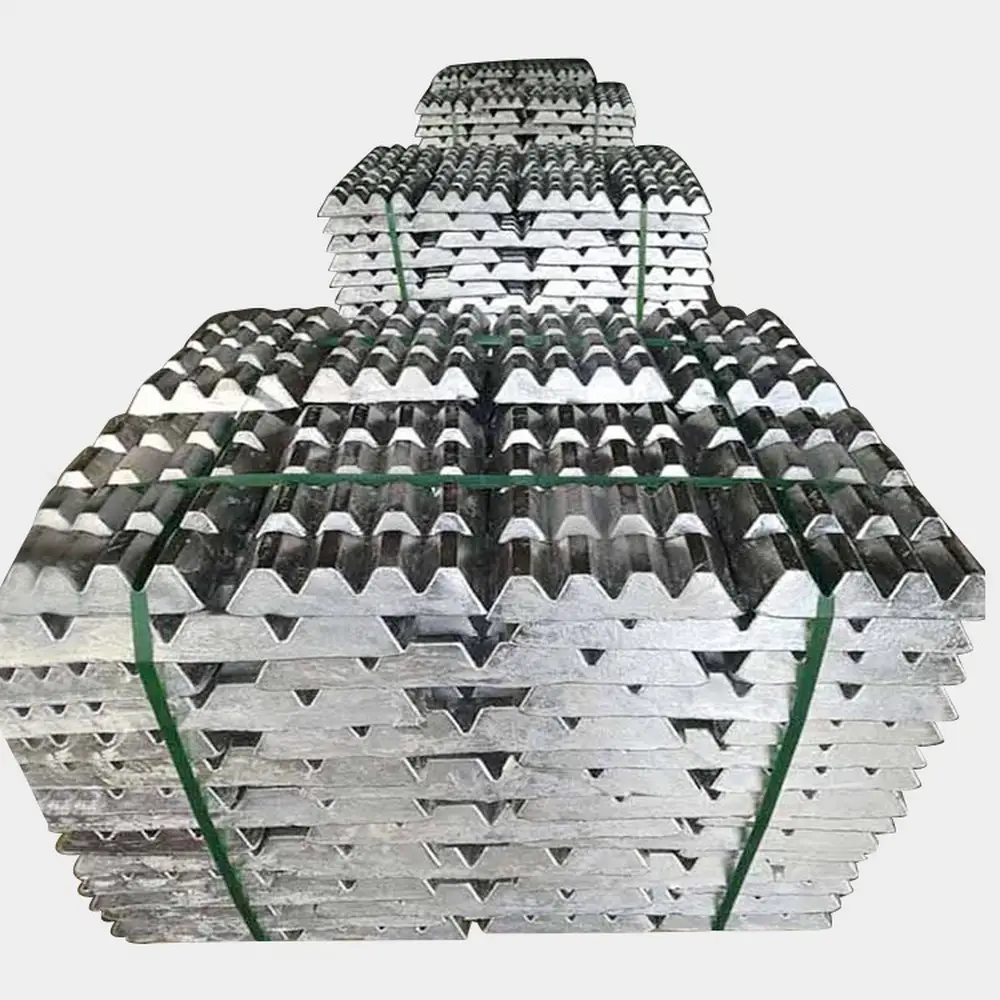

- Cut Casting Bars (CCB, 100–1000 g/bar): AlB3, AlB5, AlB8

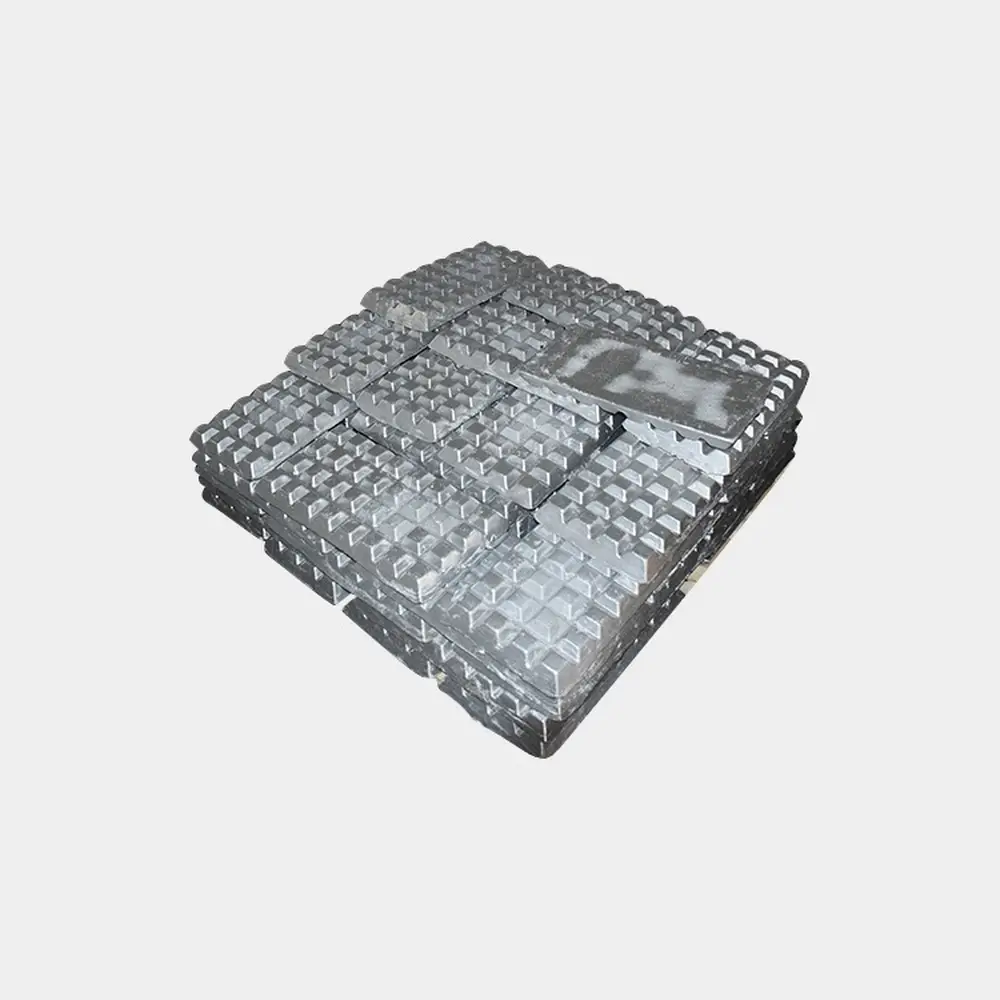

- Waffles (6–8 kg/waffle): AlB3, AlB5, AlB8

+84-(0)24-6674 6063