Aluminium Bismuth (AlBi) Master Alloy is available in AlBi5, AlBi8, and AlBi10 grades, or can be customised to meet specific bismuth content requirements. It is primarily used for bismuth addition in aluminium alloys.

With a low addition temperature and minimal bismuth burning loss, AlBi master alloy ensures efficient alloying. Bismuth is a low-melting-point metal with limited solubility in aluminium. While it slightly reduces alloy strength, it provides significant benefits by improving machinability, wear resistance, and cutting performance.

During solidification, bismuth expands, which helps improve feeding and reduce defects. In high-magnesium alloys, bismuth prevents sodium embrittlement. When added to aluminium, magnesium, or bronze alloys, it enhances machinability and wear resistance, making it highly valuable for manufacturing applications requiring precision machining.

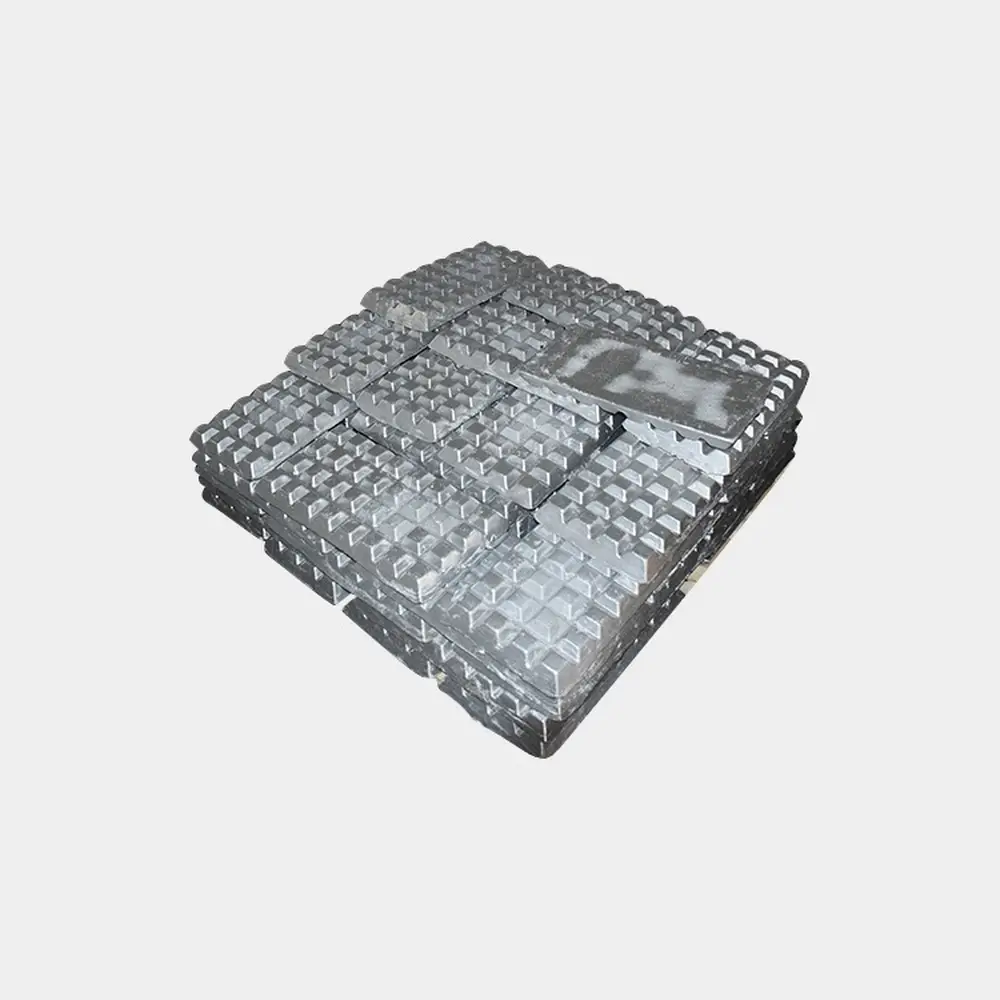

| PRODUCT | Bi(%) | BALANCE | SHAPE |

| AlBi10 | 10 | Aluminum | Waffle |

| AlBi8 | 8 | Aluminum | Waffle |

| AlBi5 | 5 | Aluminum | Waffle |

Key Features:

- Uniform structure, reducing segregation

- Improves cutting performance and machinability

- Enhances wear resistance

- Improves the mechanical properties of cast products

- Low addition temperature with minimal bismuth loss

- Reduces energy consumption and extends furnace life through lower furnace operating temperatures

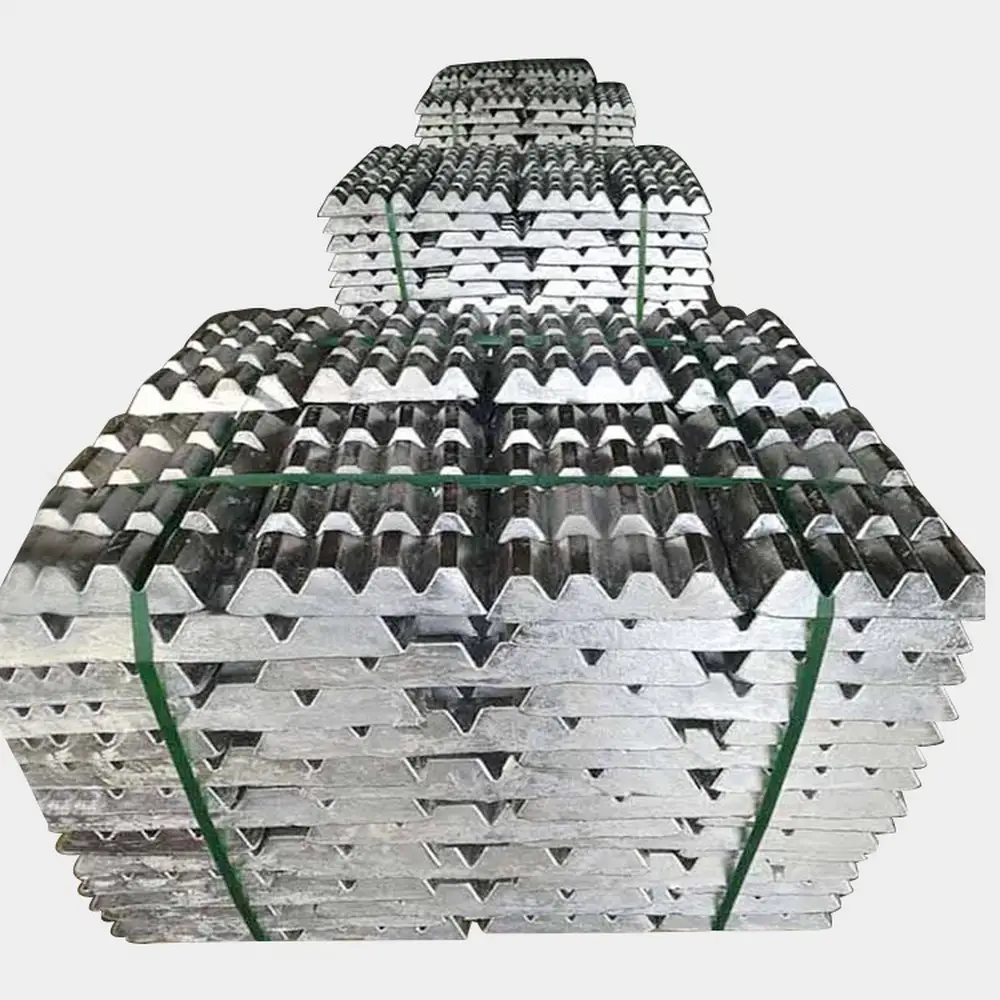

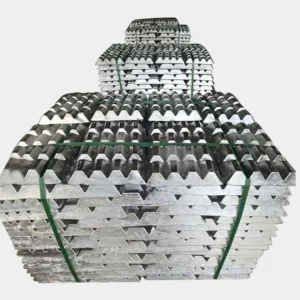

Available Specifications: Waffles (6–8 kg/waffle)

+84-(0)24-6674 6063