Aluminium Nickel (AlNi) Master Alloy is available in AlNi10, AlNi20, and AlNi50 grades, or can be customised to specific nickel content requirements. It is primarily used for nickel addition in aluminium alloys.

With a low addition temperature and minimal nickel burning loss, AlNi master alloy is an efficient and reliable method for alloying. Nickel additions significantly improve the mechanical properties of aluminium alloys at elevated temperatures, enhancing tensile strength, hardness, and heat resistance. While high nickel levels may reduce corrosion resistance and thermal conductivity, they improve the ductility, hardness, and high-temperature stability of aluminium materials, making AlNi alloys highly valuable in demanding applications.

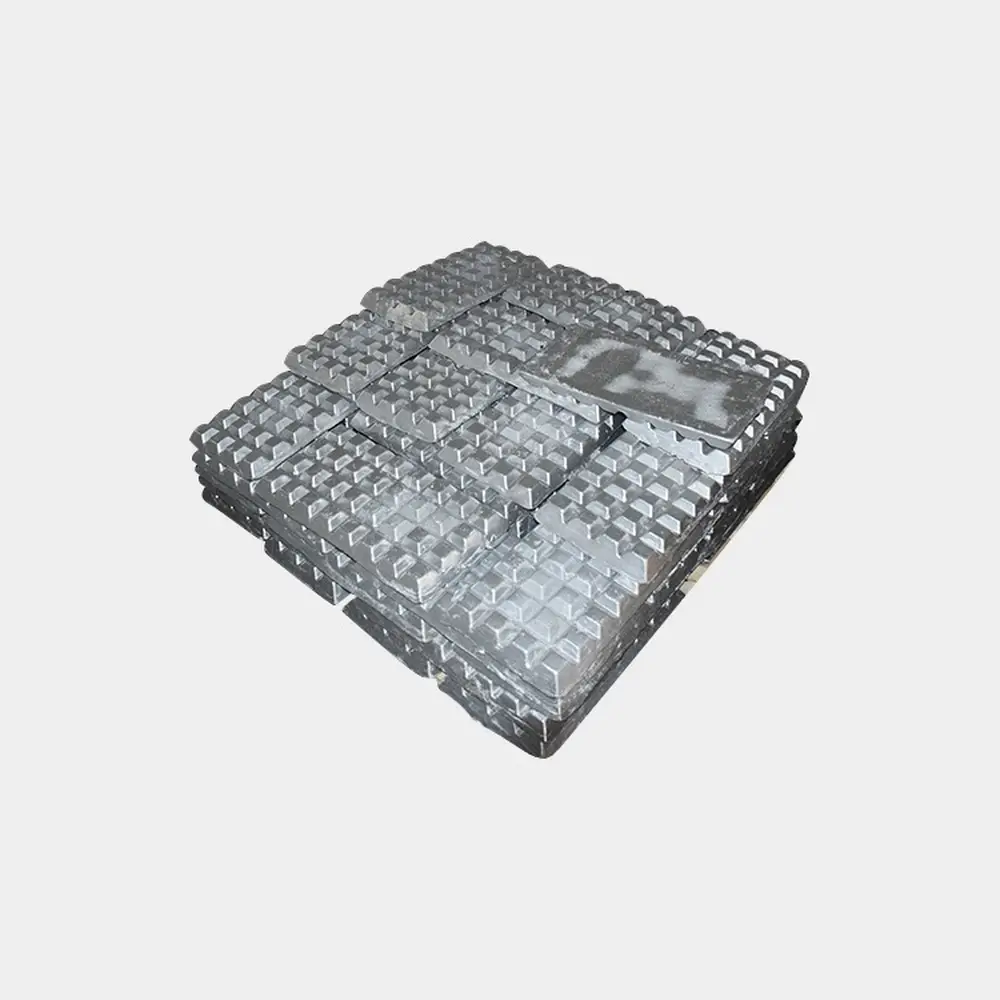

| PRODUCT | Ni(%) | BALANCE | SHAPE |

| AlNi10 | 10 | Aluminum | Waffle |

| AlNi8 | 8 | Aluminum | Waffle |

| AlNi5 | 5 | Aluminum | Waffle |

Key Features

- Uniform structure, reducing segregation

- Improves tensile strength and hardness

- Enhances heat resistance and high-temperature strength

- Improves the overall mechanical properties of aluminium alloys

- Low addition temperature with reduced nickel loss

- Contributes to lower energy consumption and extended furnace life through reduced furnace temperature requirements

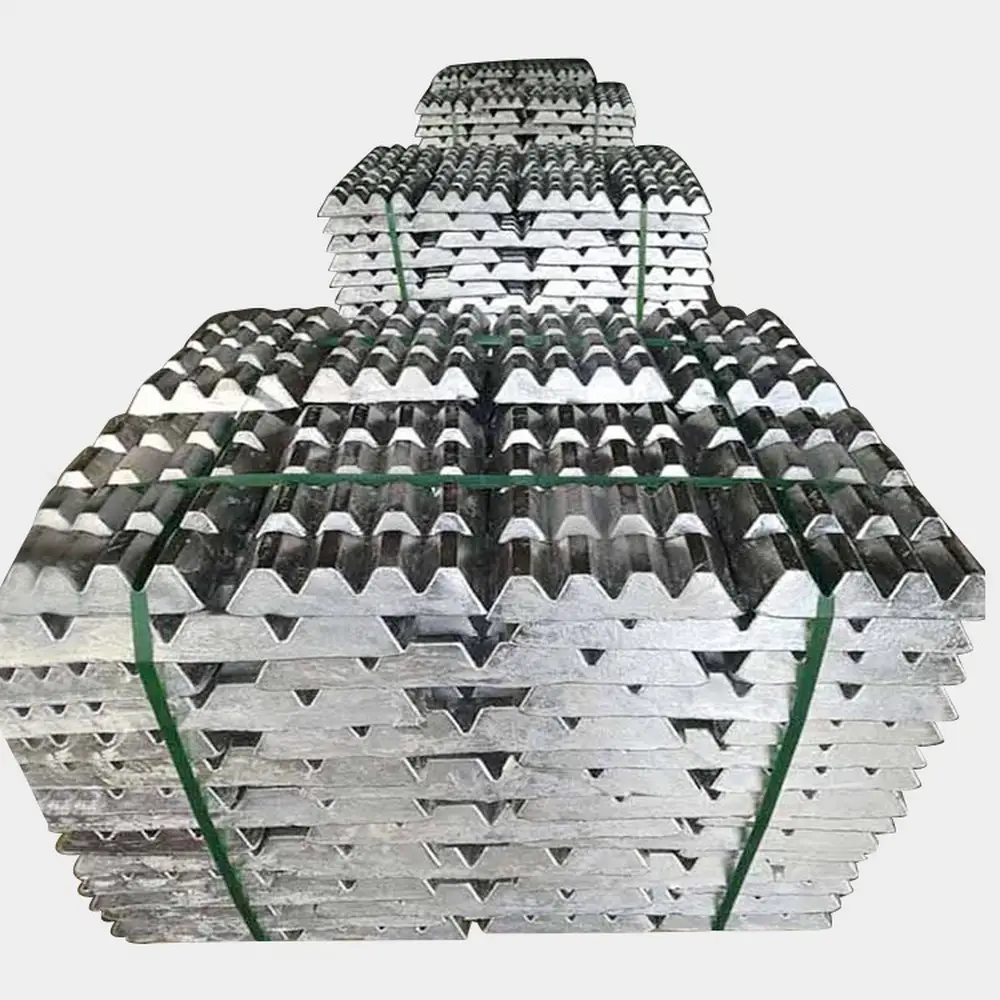

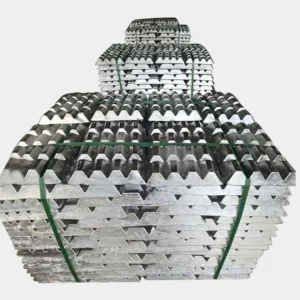

Available Specifications: Waffles (6–8 kg/waffle)

+84-(0)24-6674 6063