The Aluminium Strontium (AlSr) master alloy is a long-term modifier designed for die casting, low-pressure casting, and the modification of hypoeutectic and eutectic aluminium-silicon alloys with extended pouring times. Unlike traditional modifiers, AlSr retains its modification effectiveness even during prolonged melt holding, ensuring stable performance in large-scale and continuous casting operations.

By refining the morphology of the silicon phase in aluminium-silicon alloys—transforming coarse platelets into a fine fibrous eutectic structure—AlSr significantly improves casting soundness, mechanical strength, and overall fluidity.

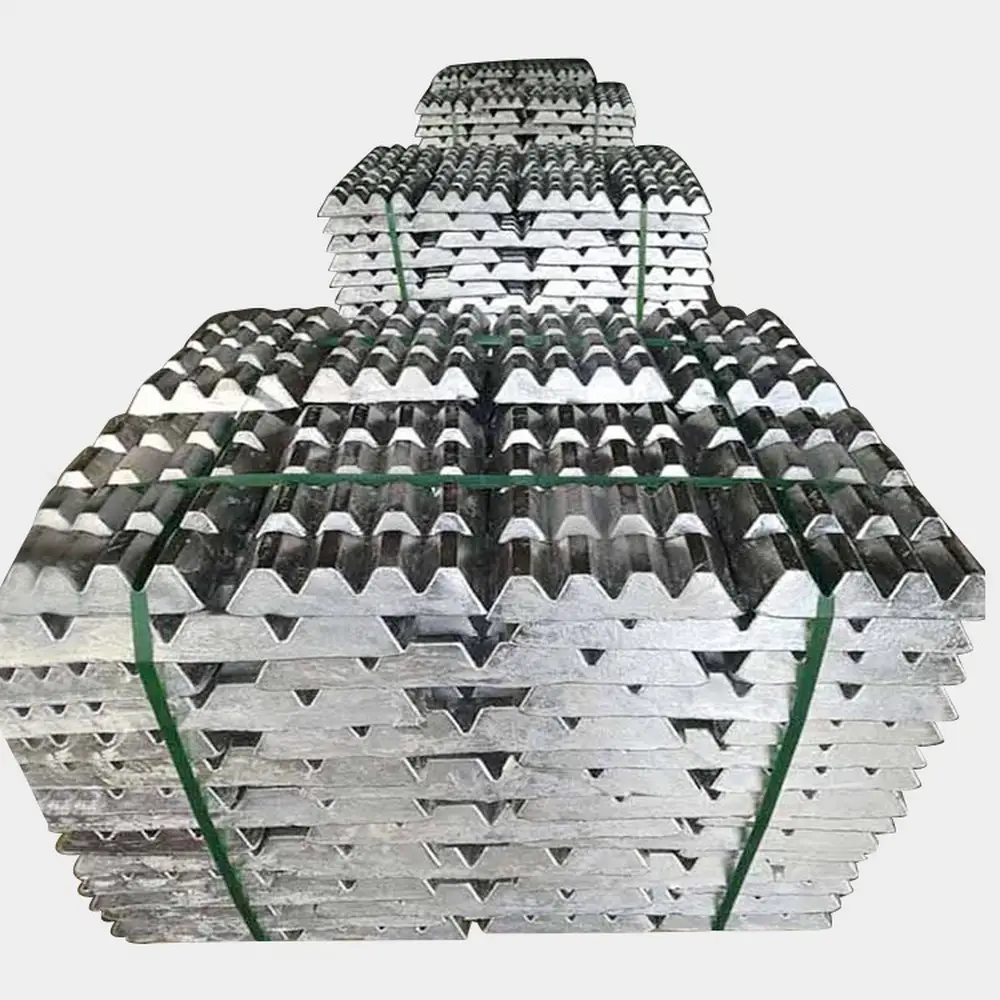

| PRODUCT | SR% | BALANCE | SHAPE |

| AlSr5 | 5 | Aluminum | Coil, CCB, Waffle, Stick |

| AlSr10 | 10 | Aluminum | Coil, CCB, Waffle, Stick |

| AlSr15 | 15 | Aluminum | Coil, CCB, Waffle, Stick |

Key Features & Advantages

- Extended modification duration – Maintains effectiveness for over 6–8 hours, and even after 4–5 remelts, ensuring reliable modification in continuous and long-cycle casting.

- Superior casting performance – Enhances structural uniformity, mechanical properties, and melt fluidity, making it ideal for large castings and high-volume production.

- Efficiency and cost-effectiveness – Easy to use, with minimal wastage, no environmental pollution, and reduced overall operating costs.

- Stable and reliable – Offers hereditary modification effects with consistent distribution and long-lasting structural refinement.

Customization Options

The Aluminium Strontium (AlSr) master alloy can be manufactured to customer specifications with varying strontium content and packaging. High-concentration alloys containing 20% or more strontium are also available upon request.

+84-(0)24-6674 6063