Aluminium Titanium master alloys are available in AlTi15, AlTi10, and AlTi5 grades, depending on the titanium content. They are widely used for titanium addition and grain refinement in aluminium alloys.

When added to molten aluminium, the master alloy produces a large number of TiAl₃ high-melting-point particles, which act as heterogeneous nucleation sites during solidification. This refines the grain structure, enhances uniformity, and significantly improves the strength, ductility, and overall mechanical performance of aluminium castings. With a low addition temperature and minimal titanium burning loss, AlTi master alloys are both efficient and cost-effective in refining applications.

| PRODUCT | Ti(%) | BALANCE | SHAPE |

| AlTi15 | 15 | Aluminum | CCB, Waffle |

| AlTi10 | 10 | Aluminum | CCB, Waffle |

| AlTi5 | 5 | Aluminum | CCB, Waffle |

Key Features

- Evenly distributed structure, reducing segregation

- Prevents cracks and minimizes casting defects

- Enhances surface quality of cast products

- Improves ductility and plasticity

- Low addition temperature with reduced titanium loss

- Strengthens overall mechanical properties

Available Specifications

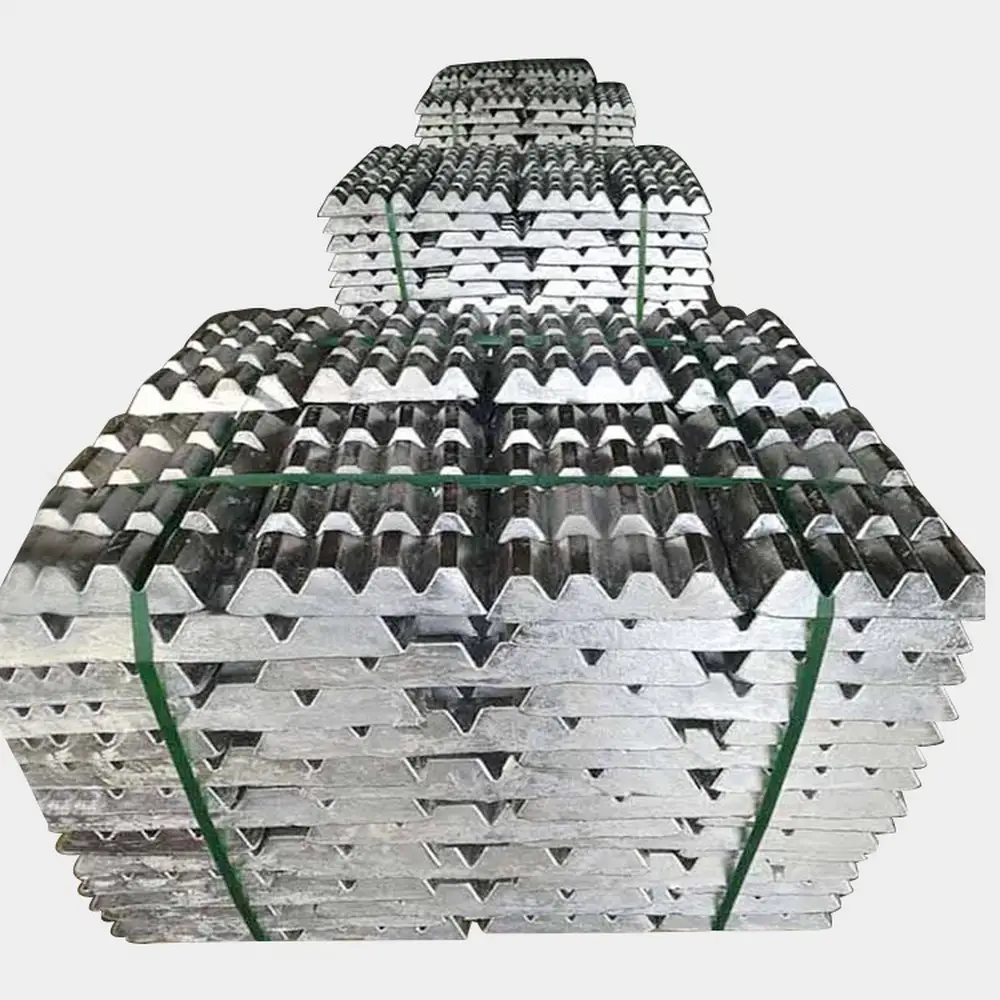

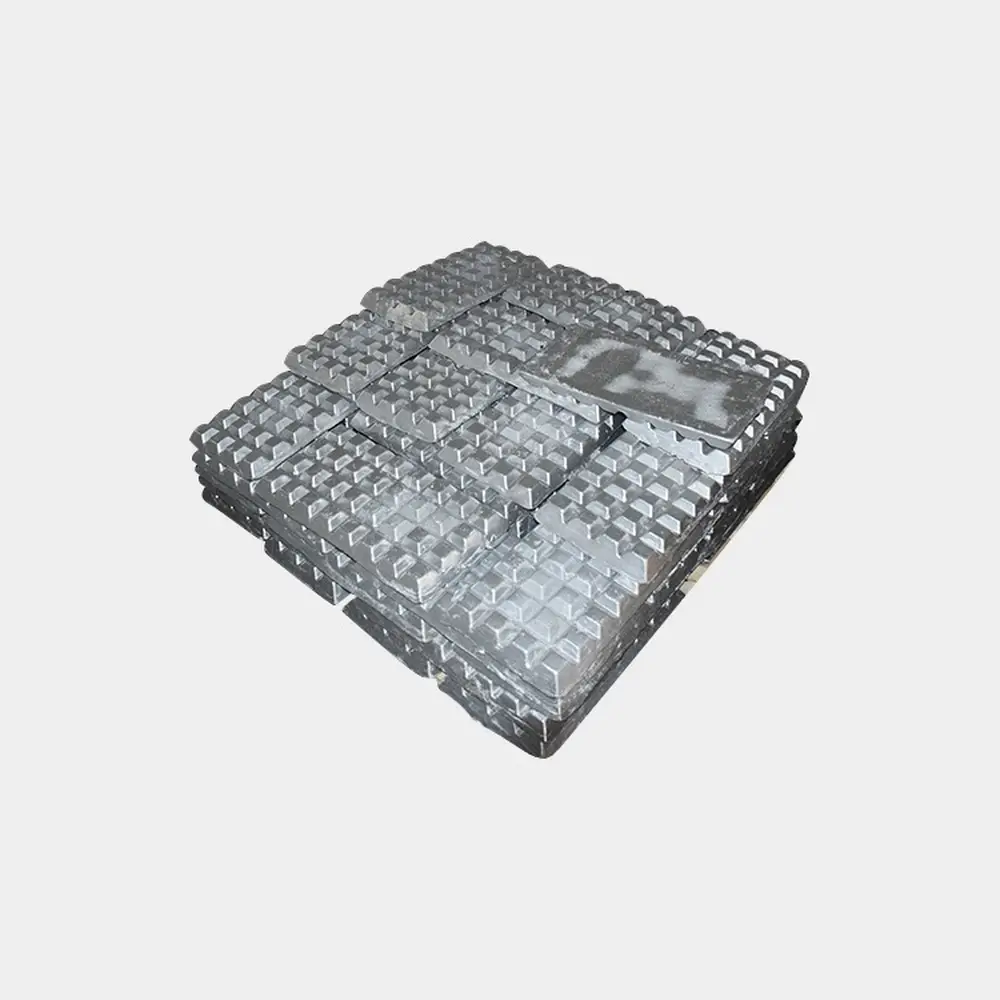

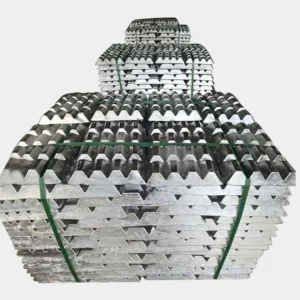

To meet customer process requirements, AlTi master alloys are supplied in multiple forms:

- Cut Casting Bars (CCB, 100–1000 g/bar): AlTi5, AlTi10, AlTi15

- Waffles (6–8 kg/waffle): AlTi5, AlTi10, AlTi15

+84-(0)24-6674 6063