Aluminium Vanadium (AlV) Master Alloy is available in AlV5 and AlV10 grades, or can be tailored to customer-specific vanadium content requirements. It is widely used in the production of aluminium alloys where vanadium addition is required.

The addition of vanadium improves the strength, increases the recrystallisation temperature, and reduces the thermal expansion coefficient of aluminium alloys. These enhancements make AlV master alloys highly suitable for applications demanding improved mechanical stability and dimensional reliability under thermal stress.

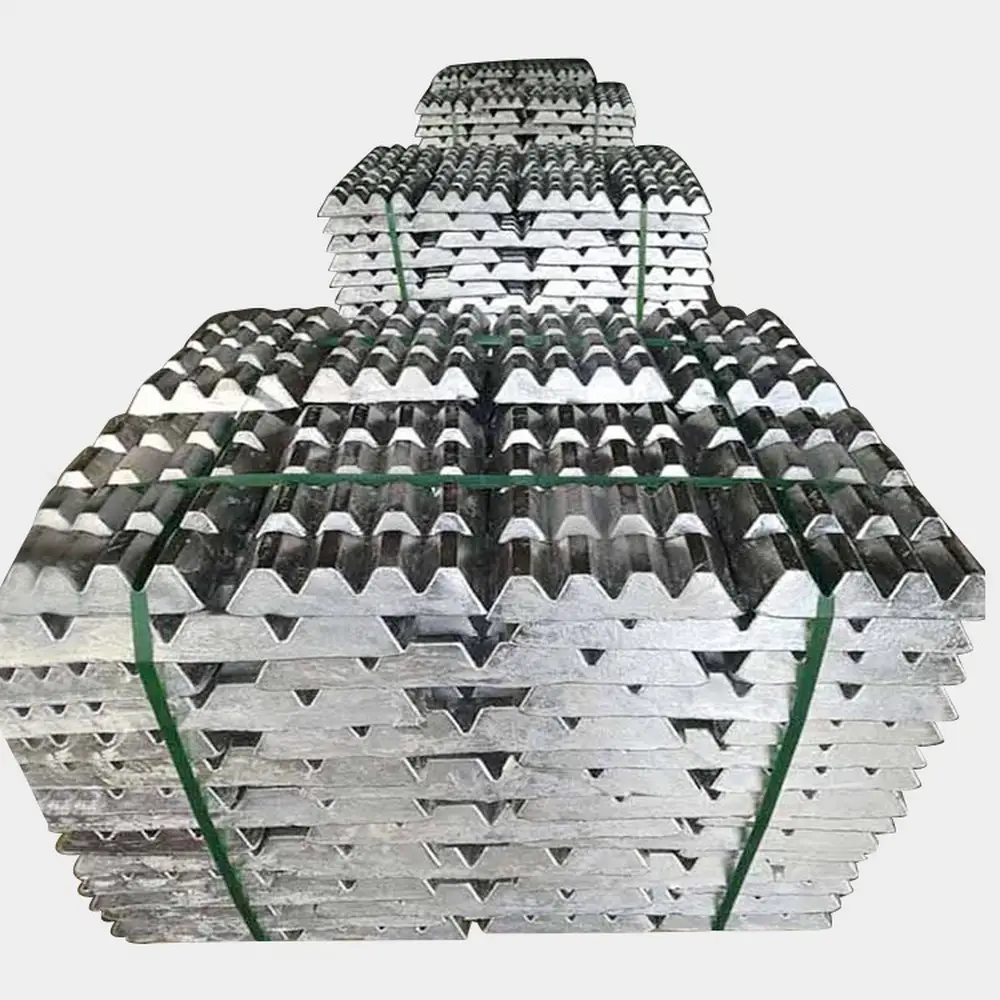

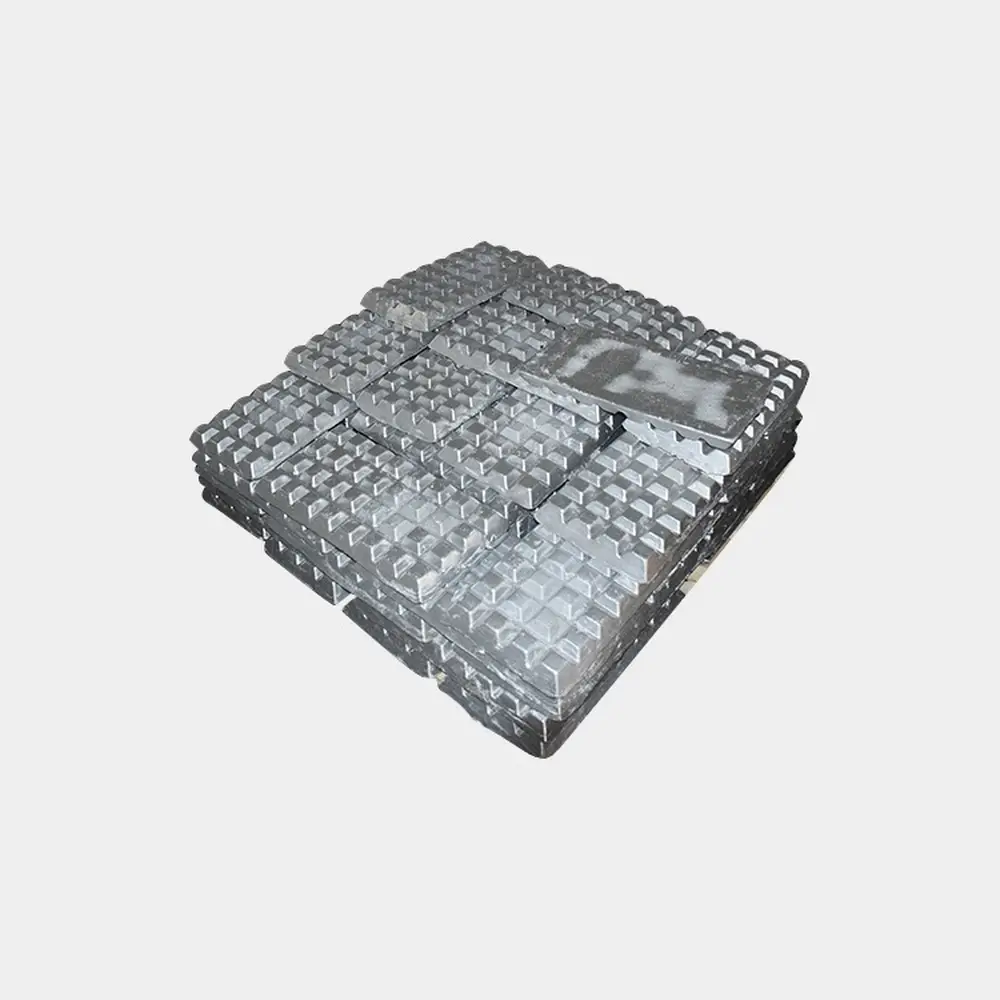

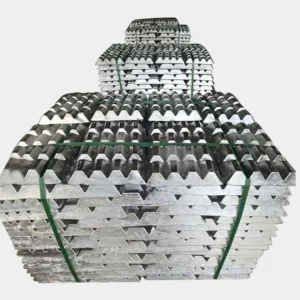

| PRODUCT | V(%) | BALANCE | SHAPE |

| AlV10 | 10 | Aluminum | Waffle |

| AlV5 | 5 | Aluminum | Waffle |

Key Features

- Uniform structure, reducing segregation in alloys

- Prevents cracks and minimises casting defects

- Improves the surface quality of finished products

- Minimises dross formation and reduces hydrogen solubility

- Low addition temperature with minimal vanadium loss

- Enhances the mechanical properties of aluminium alloys

- Contributes to lower energy consumption and extended furnace life by enabling reduced furnace temperatures

+84-(0)24-6674 6063