Aluminium Chromium (AlCr) Master Alloy is available in AlCr5 and AlCr10 grades, or can be customised to meet specific chromium content requirements. It is used for chromium addition and grain refinement in aluminium alloys.

With a low addition temperature and minimal chromium burning loss, AlCr master alloy is an efficient way to introduce chromium into aluminium. Chromium is a common alloying element in Al-Mg-Si, Al-Mg-Zn, and Al-Mg systems. It forms intermetallic compounds such as (CrFe)Al₇ and (CrMn)Al₁₂, which hinder recrystallisation, improve toughness, strengthen the alloy, and reduce sensitivity to stress corrosion cracking (SCC).

Since the solubility of chromium in aluminium is limited (only 0.8% at 600 °C), the use of master alloys is the most effective method for uniform and controlled chromium addition.

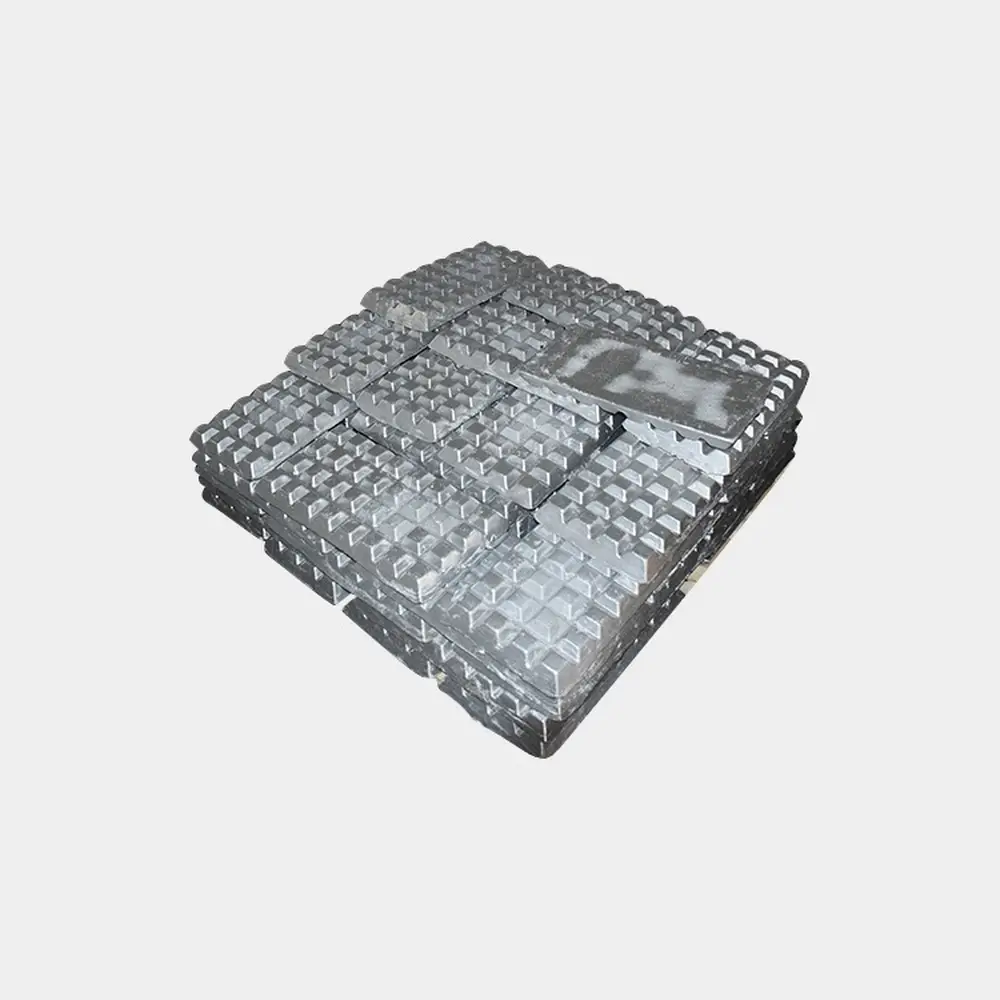

| PRODUCT | Cr(%) | BALANCE | SHAPE |

| AlCr10 | 10 | Aluminum | Waffle |

| AlCr5 | 5 | Aluminum | Waffle |

Key Features

- Uniform structure, minimising segregation

- Reduces sensitivity to stress corrosion cracking (SCC)

- Enhances toughness and surface quality

- Improves overall mechanical properties

- Low addition temperature and reduced chromium loss

- Energy-efficient, extending furnace life with lower operating temperatures

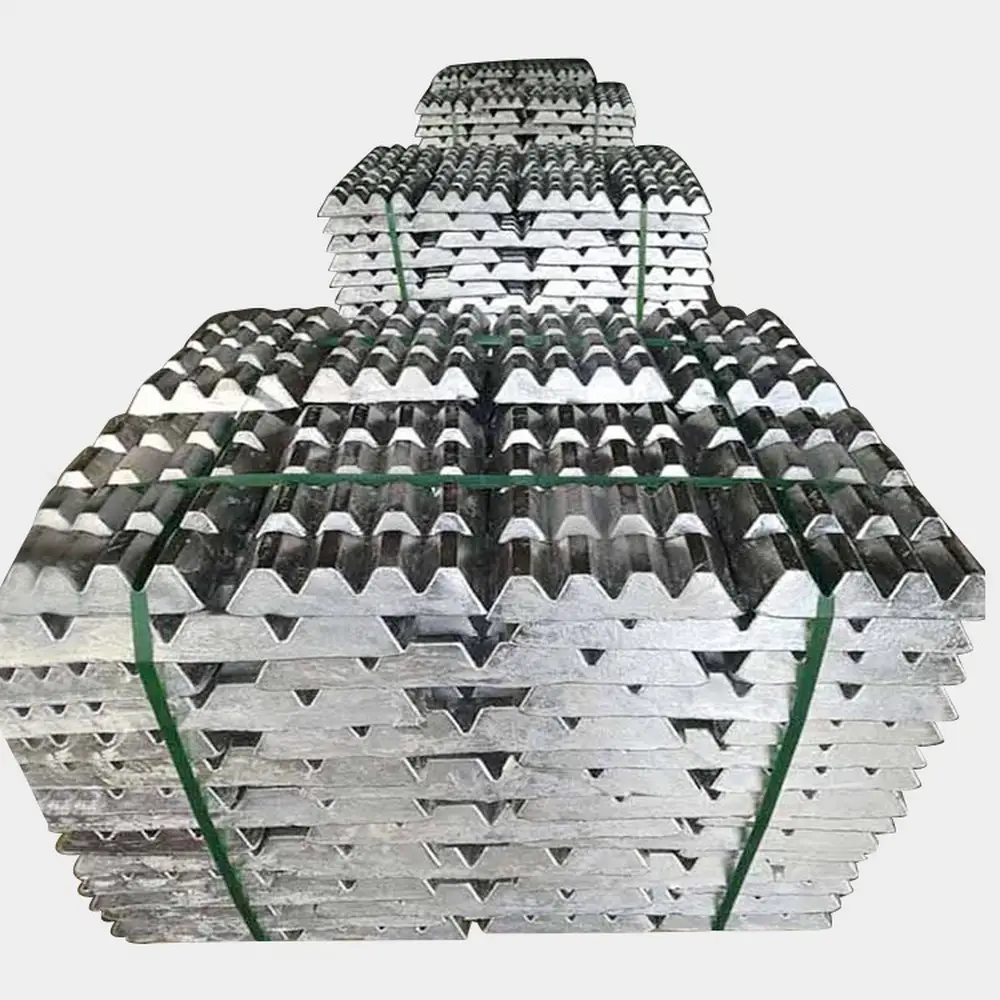

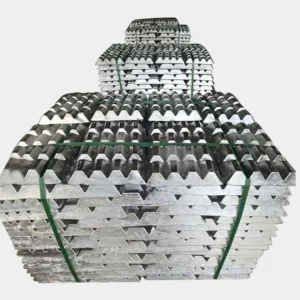

Available Specifications: Waffles (6–8 kg/waffle)

+84-(0)24-6674 6063