The Aluminium Titanium Boron (AlTiB) Master Alloy is widely recognised as one of the most effective grain refiners for aluminium and aluminium alloys. By preventing the formation of coarse equiaxed, columnar, and feathered crystals, it significantly enhances the mechanical strength, plasticity, and overall physical properties of aluminium castings.

The refining mechanism is closely linked to the presence of TiAl₃ and TiB₂ particles. Smaller and more active nuclei improve grain refinement, prevent agglomeration, and ensure uniform distribution. When introduced into molten aluminium, AlTiB releases a large number of heterogeneous nucleation cores, which influence crystallisation during solidification and result in finer, more uniform alloy grains.

| PRODUCT | Ti (%) | B (%) | BALANCE | SHAPE |

| AlTi5B1 | 5 | 1 | Aluminum | Coil, CCB, Waffle, Stick |

| AlTi3B1 | 3 | 1 | Aluminum | Coil, CCB, Waffle, Stick |

| AlTi5B0.2 | 5 | 0.2 | Aluminum | Coil, CCB, Waffle, Stick |

Key Features

- Even grain distribution, reducing segregation

- Prevents hot cracks and minimises casting defects

- Enhances product surface quality and appearance

- Improves ductility and plasticity

- Strengthens the overall mechanical properties of aluminium alloys

Available Specifications

AlTiB master alloy can be supplied in different grades and forms according to customer requirements:

- Sticks (Ø 9.5 mm): AlTi5B1, AlTi3B1, AlTi5B0.2

- Cut Casting Bars (100–1000 g/bar): AlTi5B1, AlTi3B1, AlTi5B0.2

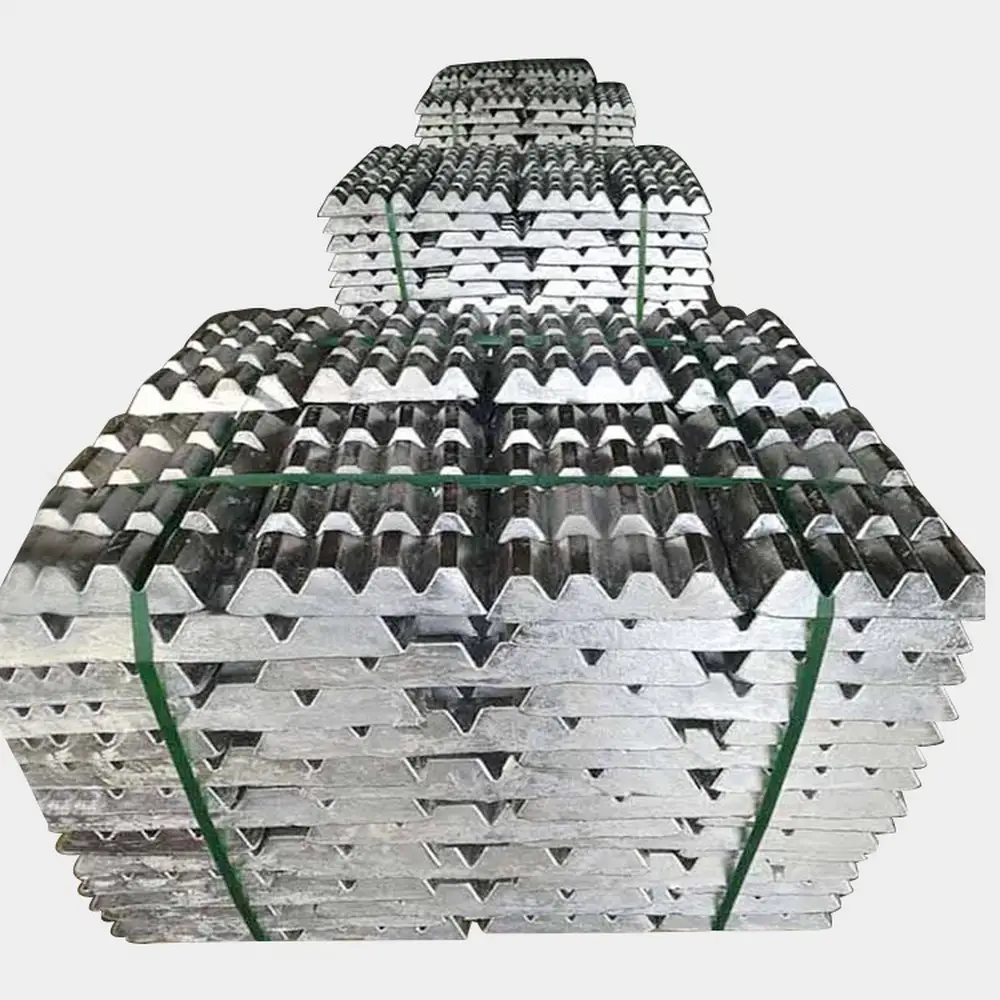

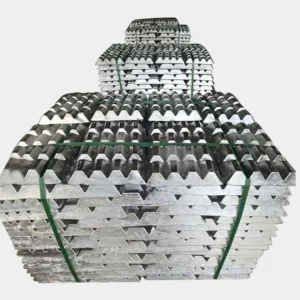

- Waffles (6–8 kg/waffle): AlTi5B1, AlTi3B1, AlTi5B0.2

- Coils (180–220 kg/coil): AlTi5B1, AlTi3B1, AlTi5B0.2

+84-(0)24-6674 6063