With a low addition temperature and minimal zirconium burning loss, AlZr master alloy is especially effective in advanced alloy systems. Small zirconium additions are commonly used in ultralight Al-Li alloys and Al-Zn-Mg-Cu high-strength alloys. During casting and homogenization, finely dispersed Al₃Zr particles are formed, which refine grains, inhibit recrystallisation during deformation, and provide precise control over grain size and morphology.

The result is significant improvements in hardenability, weldability, fracture toughness, and stress corrosion resistance, making AlZr alloys highly valued in aerospace, automotive, and other high-performance applications.

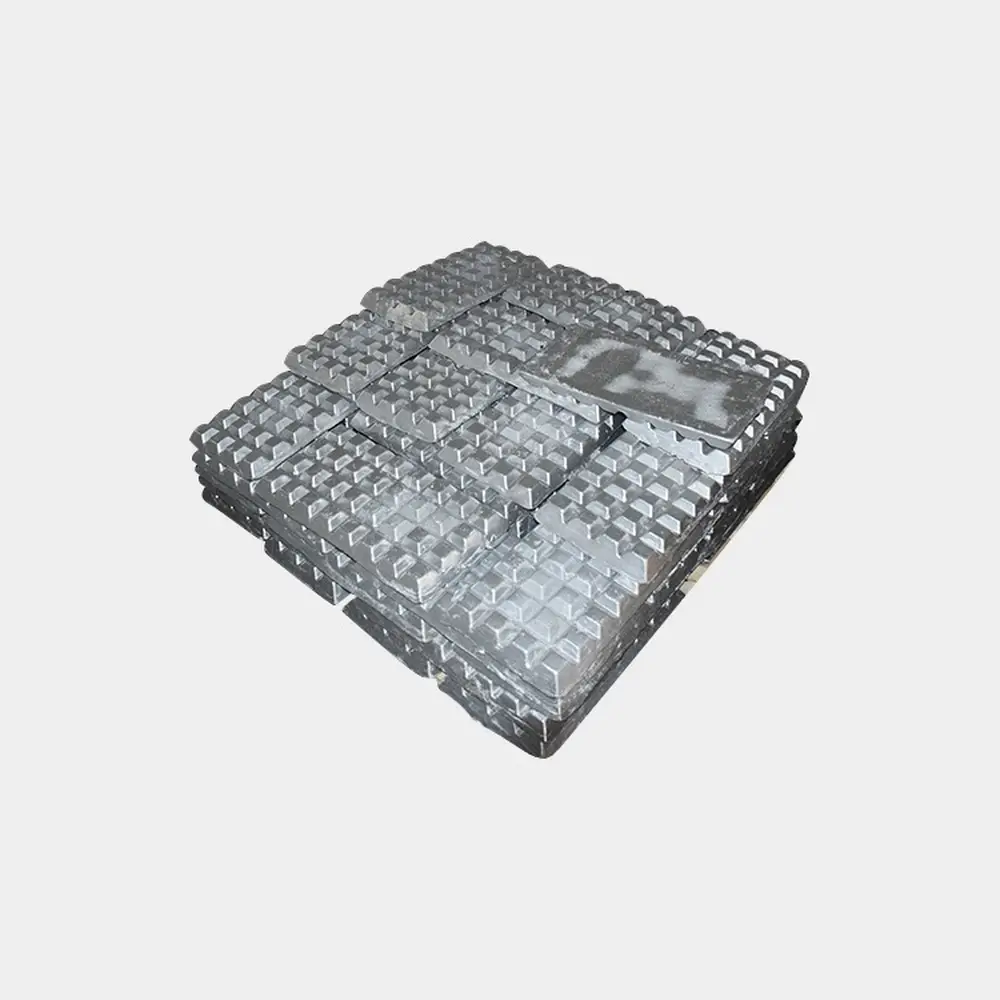

| PRODUCT | Zr(%) | BALANCE | SHAPE |

| AlZr10 | 10 | Aluminum | Waffle |

| AlZr5 | 5 | Aluminum | Waffle |

Key Features

- Even grain distribution, reducing segregation

- Prevents cracks and minimises casting defects

- Enhances product surface quality and consistency

- Reduces dross formation and hydrogen solubility

- Low addition temperature with minimal zirconium loss

- Improves the overall mechanical properties of aluminium alloys

- Contributes to reduced energy consumption and extended furnace life by enabling lower furnace operating temperatures

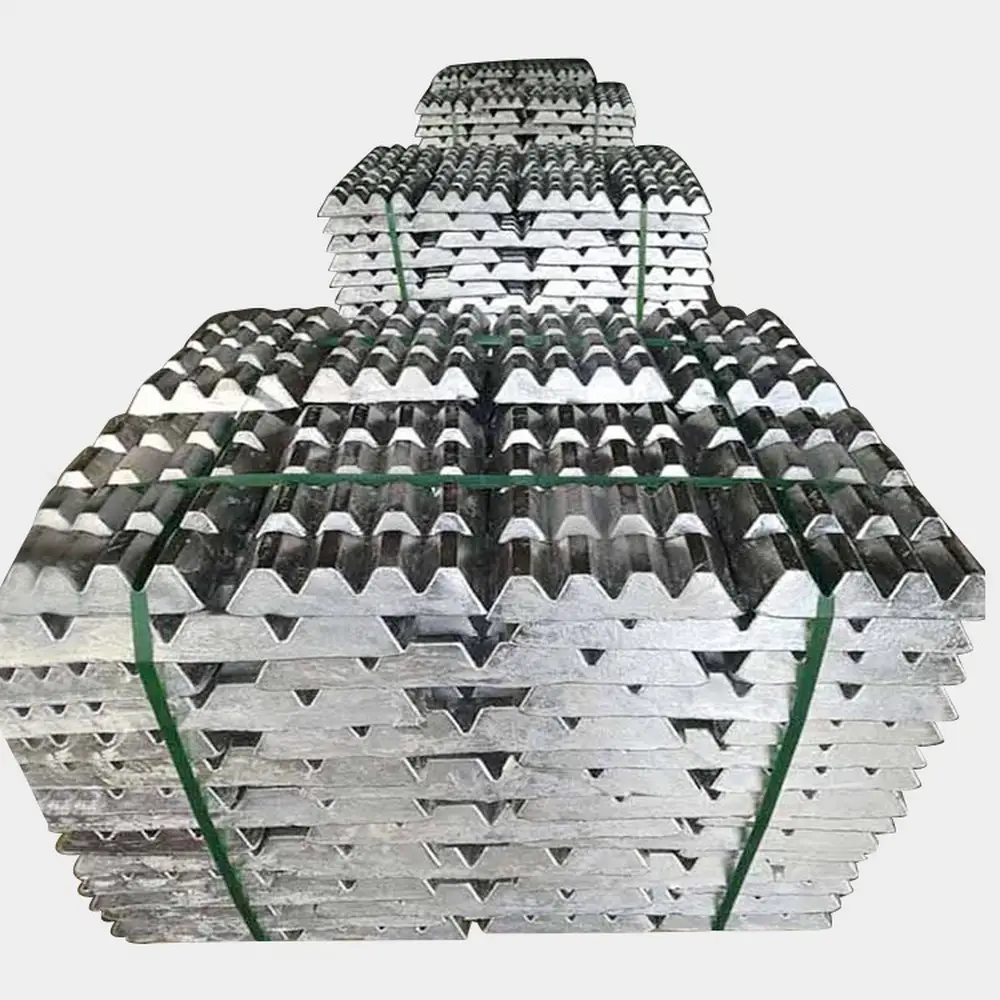

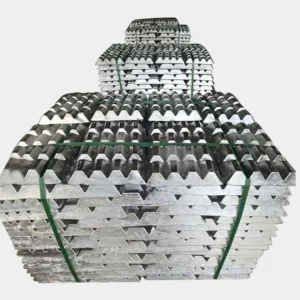

Available Specifications: Waffles (6–8 kg/waffle)

+84-(0)24-6674 6063